KF200

KELISAIKE

KF200-LASER

| Availability: | |

|---|---|

| Quantity: | |

Product Description

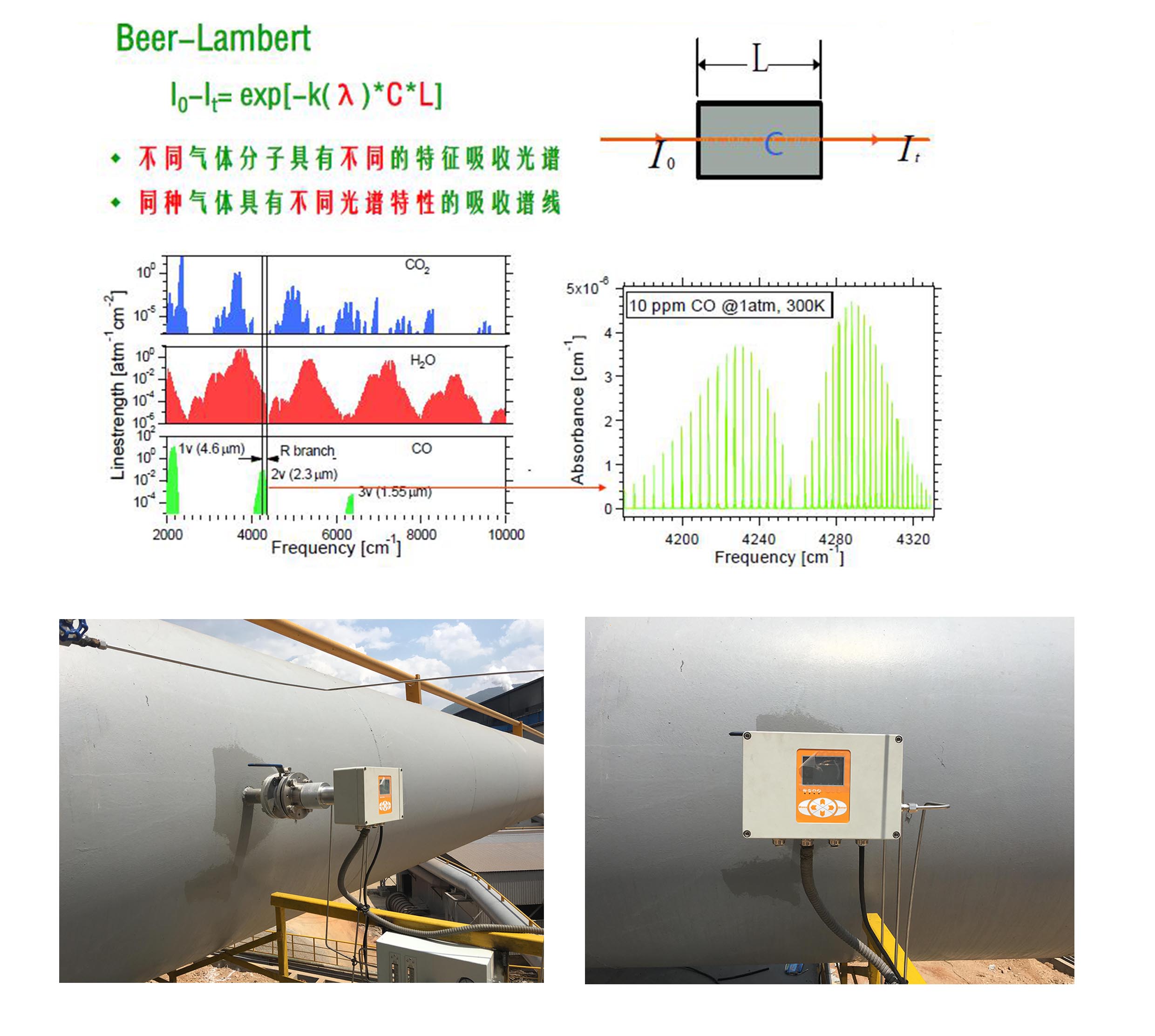

The KF200 Series Laser Gas Analyzer is developed aiming at industrial on-line analyzing, and online environmental monitoring. Based on the semiconductor laser absorption spectroscopy (DLAS) technology, it is developed with features of an integrated design and high level of integration.

With various types of the KF200 series laser gas analyzer, including in-situ probing type, by-pass type, multi-channel and disc-mounted type, etc., gases like O2, CO, NH3, CO2, CH4, H2O, HC, HF, etc., can all be analyzed. The concentration analyzing of target gases includes the macro-analysis and micro-analysis.

Technical Principle:

Modulate laser (tunable) wavelength by using the current and temperature to scan the specific absorption peak of the measured gas (no background gas absorption), and then get the second harmonic of the gas absorption. By using the second harmonic information and the broadening of the gas, the concentration of the gas can be calculated.

l The TDLAS technology is adopted for in-situ online gas analyzing;

l Double-proof probe design negates positive pressure purge, with no additional data processing unit, a simple compact structure and high reliability;

l Using high-power lasers, no fibre coupling, suitable for harsh working conditions (such as excessive dust);

Technical Specifications:

Technical Data | linearity error | ≤ ±1% F.S. |

Span drift | ≤ ±1% F.S./6 months | |

Repeatability | ≤ 1% | |

calibration period | ≤ 1 time/6 month | |

Explosion-proof Grade | Ex d IIC T6 | |

Protection levels | IP66 | |

Response Time | Warming-up time | ≤ 15 min |

Response time(T90) | ≤ 1 s | |

Interface Signals | Analogue outputs | 2-wire 4–20 mA signal input (Isolated, Max. load 750 Ω) |

Relay output | 3-wire relay (24 V,1A) | |

Digital Communication | RS485/RS232/GPRS | |

Analogue inputs | 2-way 4–20 mA input (temperature-pressure compensation) | |

Laser Safety Standard | GB7247.1-2001 (idt IEC 60825-1:1993) | |

Operating Conditions | Storage Temperature | -30℃ ~ +60℃ |

Ambient temperature | -40℃ ~ +80℃ | |

EMC | IEC 6100-4-2, IEC 6100-4-3, IEC 6100-4-4, IEC 6100-4-5,IEC 6100-4-11 | |

Gas jet | 0.3 ~ 0.8 MPa industrial nitrogen inlet and purification instrument gases, etc. | |

Consumption | < 20 W | |

Power | 24 V DC (18-36 V DC), 220 V AC | |

Gas Detection Limits:

Detection Gas Type | Detection Limit | Detection range |

O2 | 0.01% Vol. | (0-1)%Vol., (0-100)%Vol. |

CO2 | 10 ppm | (0-1000)ppm,(0-100)%Vol. |

H2S | 20 ppm | (0-2000) ppm, (0-100)%Vol. |

HCl | 0.1 ppm | (0-50) ppm,(0-100)%Vol. |

NH3 | 0.1 ppm | (0-10) ppm, (0-100)%Vol. |

C2H2 | 0.1ppm | (0-10) ppm, (0-100)%Vol. |

CO | 10 ppm | (0-1000) ppm, (0-100)%Vol. |

H2O | 0.3 ppm | (0-50) ppm, (0-100)%Vol. |

HF | 0.02 ppm | (0-5) ppm, (0-10000) ppm |

HCN | 0.3 ppm | (0-30) ppm, (0-1)%Vol. |

CH4 | 0.4 ppm | (0-40) ppm, (0-100)%Vol. |

C2H4 | 0.6 ppm | (0-60) ppm, (0-100)%Vol. |

Note:

1) The test conditions include a 1-meter optical path, 1 bar gas pressure, and a 300 K gas temperature.

2) Increasing the optical path will proportionally lower the detection limit.